I own a NordicTrack treadmill for years.

During this period, I have faced some common problems most treadmill will have after a certain period of time.

One of these is the treadmill belt tends to slow down or completely stop when I step on it, sometimes it even squeaking and making weird noises.

In this case, the treadmill belt will run normally when no load on it, but will slow down with the load.

I knew this was not normal as the treadmill won’t response like this when it is still new.

In this post, I have listed the possible reasons for this treadmill belt movement issue when weight applies on it.

Read: How To Solve Treadmill Belt Slipping and Sticking Issue

Treadmill Belt Slows Down or Stops When Step On It

- Belt tension and alignment

When the belt tension is too low, you might notice the belt tends to slip a bit when you step on it.

Sometimes it even slows down because it does not have enough friction to move.

Make sure to adjust the belt tension at an appropriate level so that the traction between treadmill motor and running belt can be maintained.

Besides, if your treadmill belt is off centered, or slid to one side, it might cause more friction between the belt and the deck and gets hot easily.

To fix this issue, you would need to adjust the belt tension and make the running belt located at the center again.

Here is my video on how to fix the running belt off centered issue.

I created this table for you to know how to adjust the belt tension, depending on which side your belt slid to.

| Condition | Why This happens? | Rotate Clockwise or Anti-Clockwise? |

|---|---|---|

| Belt slide to the LEFT side | - Tension at the left side is too low - Tension at the right side is too high | - Rotate the tension screw at the left side Clockwise to increase the tension OR - Rotate the tension screw at the right side Anti-Clockwise to decrease the tension |

| Belt slide to the RIGHT side | - Tension at the right side is too low - Tension at the left side is too high | - Rotate the tension screw at the right side Clockwise to increase the tension OR - Rotate the tension screw at the left side Anti-Clockwise to decrease the tension |

Besides, I would suggest you to lubricate the running regularly to reduce the friction between the running and the deck.

The increased friction might cause belt related problem as the belt won’t be able to move smoothly.

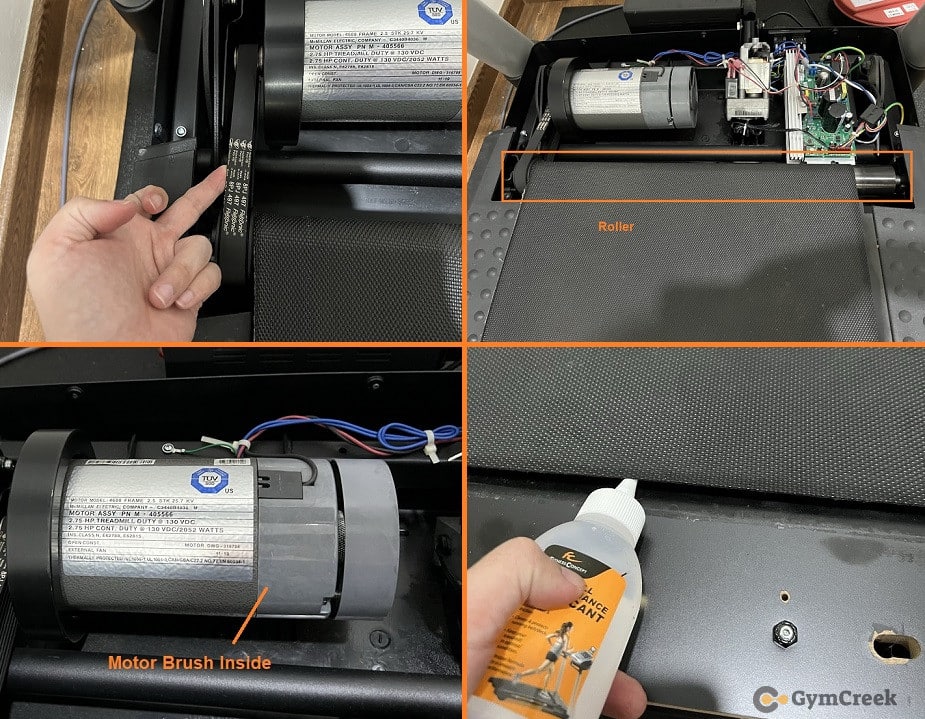

I use a common lubricant for my treadmill belt as shown in the image below.

Related:

- Motor issue

Each treadmill motor is designed to move the running belt within the acceptable load range.

I noticed that in my case, when it is still new, my treadmill motor was so powerful and it always output enough force to move the belt.

However, it has been operating since few years back, the motor brushes might be slightly worn-out.

Yes, it still can move the belt but just not as powerful as it was especially when I step on it as more load applied.

The motor might not have output enough force to accommodate with my weight hence I can feel it slows down.

There nothing much you can do if the motor brushes are worn out unless you replace it with a new one.

Read: Treadmill motor overheating issue

- Speed Sensor malfunction

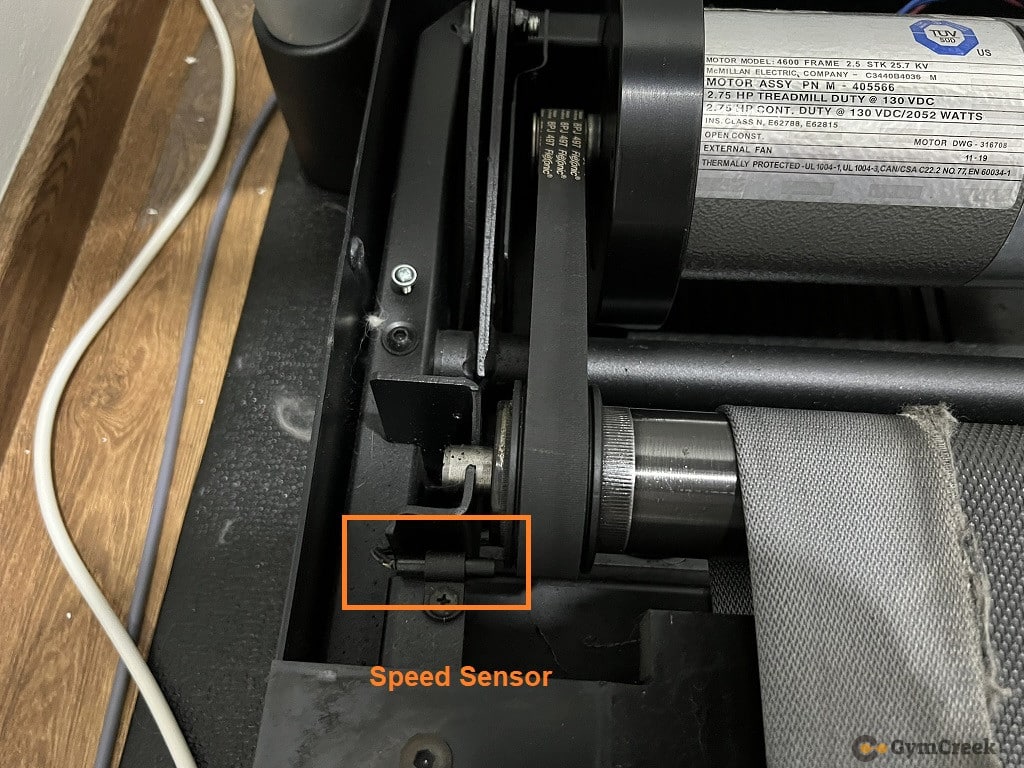

Besides, when I removed the motor hood of my treadmill, I noticed that there is a speed sensor located near the roller and the belt to monitor the speed as shown in the image below.

The function of the sensor is to help the treadmill to regulate speed.

When you step on it, there are more load applied on the deck and the roller.

In normal case, when the speed control system notices the slowing down in belt movement via the speed sensor, it tends to make the motor run faster to reach the desired speed.

If the speed sensor is faulty, the treadmill won’t be able to operate at the desired speed.

- Drive belt

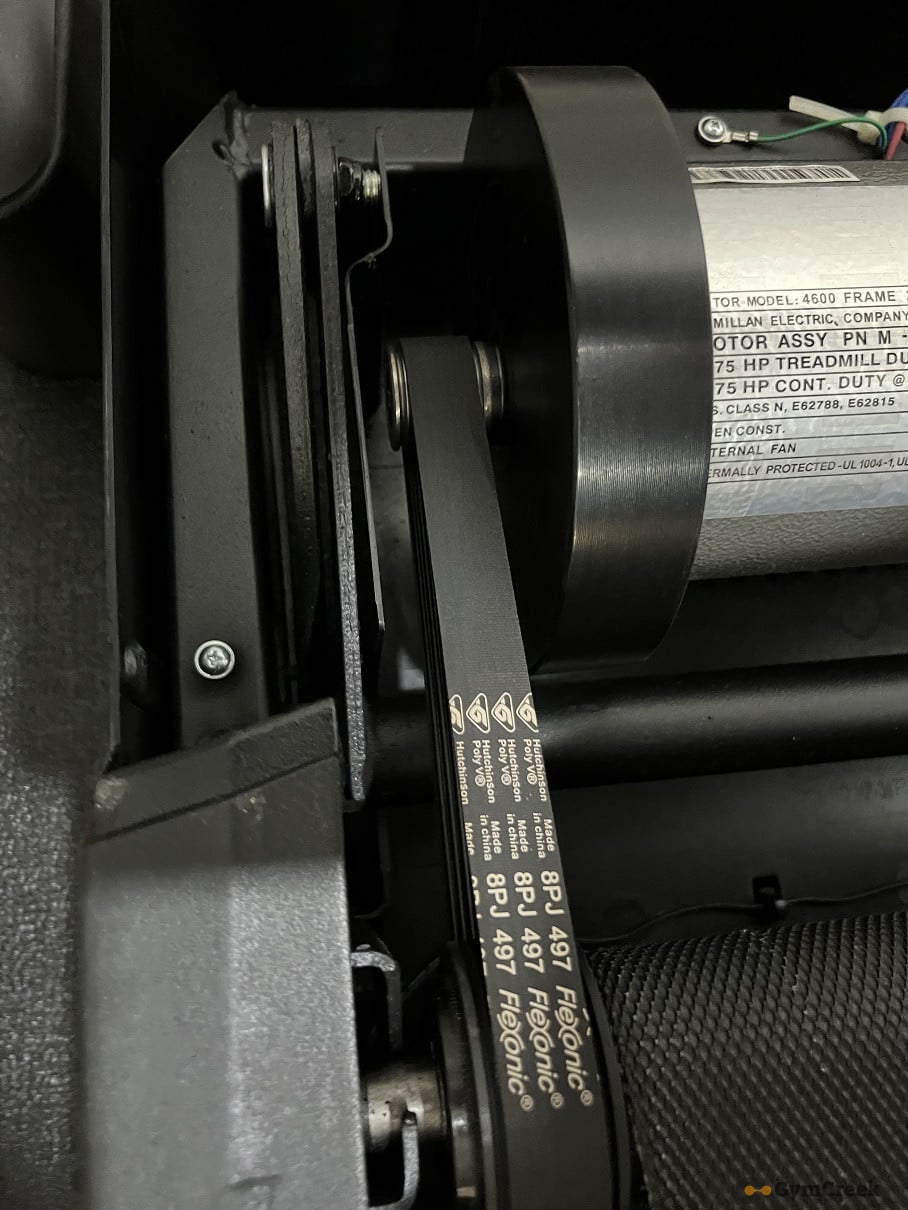

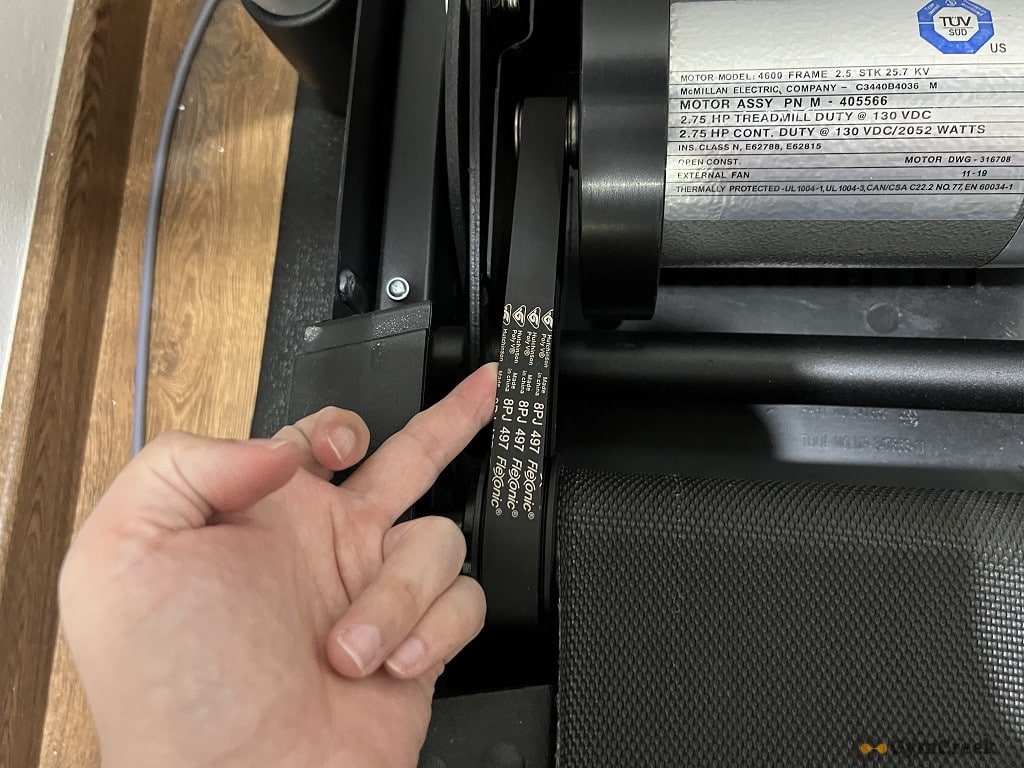

As you can see from my image below, the drive belt connects the running motor to the roller.

The roller then starts to roll and move the running belt at the same time.

The drive belt is essentially the “Connection Point” between the motor and the running belt as shown my video below:

If the drive belt is loosen, there won’t be enough friction between the motor and the roller to move smoothly.

Hence, it would result in the belt slows down or completely stop issue when you step on it.

You may simply tighten it, and check the drive belt tension using your hand as shown in the image below.

The drive belt tends to worn out after few years, make sure to replace it with a new one if this happens.

- Deck and roller problem

The running deck of treadmill is commonly made out of wood, and is an important support for the belt.

As you know, wood tends to crack over time or when excess load is applied on it.

To inspect if there is any crack on the running deck, you would need to remove the running belt on it.

This is how my treadmill running deck looks like after the belt removal. (The side holes are normal for Screws, not crack)

This creates uneven surface especially when you step on it.

With uneven surface, the belt not able to move smoothly and would slow down.

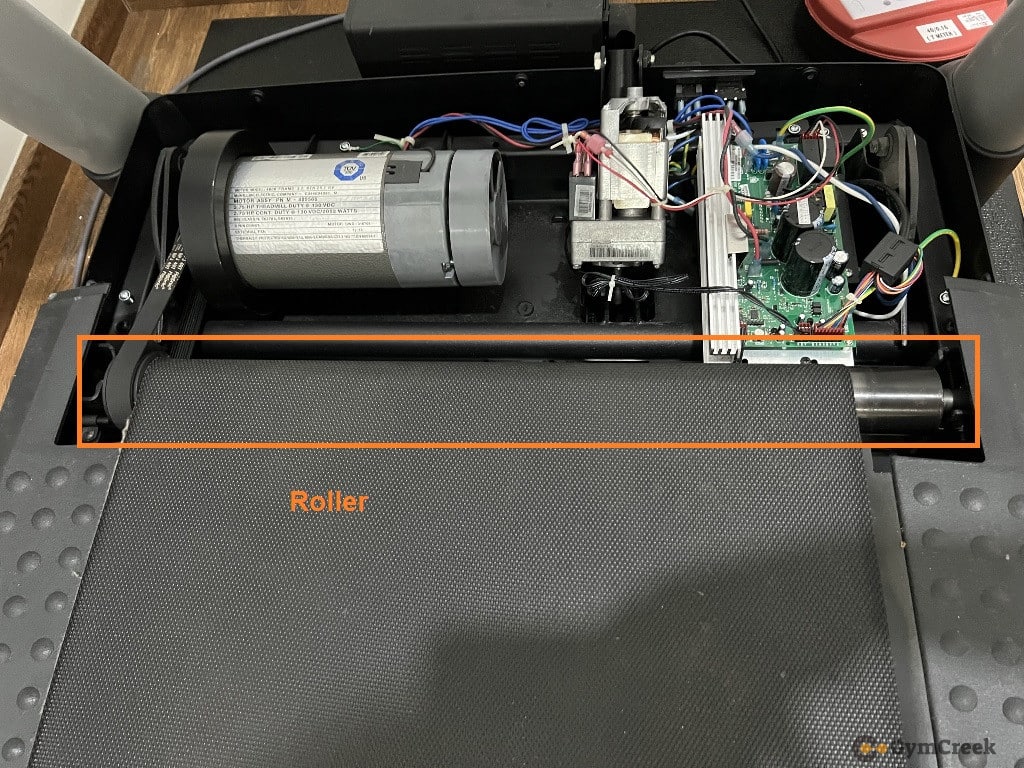

As you can see from the image below, the roller is another important part that connects the motor and belt as I mentioned before.

Make sure the roller is aligned properly and tighten.

As shown in the image below, this is how the front roller looks like without running belt on it.

Loosen roller would create an unstable situation and uneven movement and it would eventually cause the belt to slows down when someone step on it.

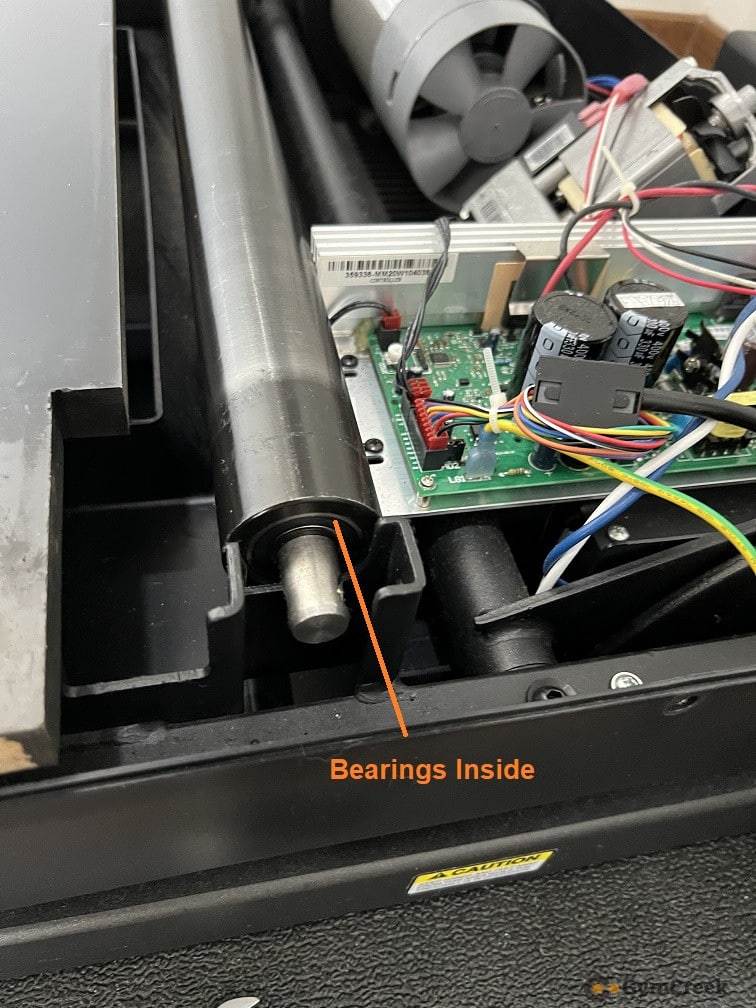

Besides, you may inspect the bearings of the roller.

As you know, the bearings in the rollers are so important to keep the roller to roll smoothly.

If you notice that there are bearing dropped on the floor, that’s mean the bearings inside the roller are not incomplete.

The bearings should be stay inside the roller unless the roller is damaged.

In this case, you can either replace the whole roller, or replace the worn-out bearings in the roller.

- Weight Limit

Do you know that each model of treadmill has it own weight limit it can handle?

If the weight of the treadmill user is more than the weight limit the treadmill can handle, sometimes the treadmill will just slow down or completely stop.

This is due to the motor unable to output enough force to move such load.

I would recommend you to check the weight limit of your treadmill model.

You can either find it on the treadmill user manual or Google it online.

Tips: You may find a complete list of Weight Limit of NordicTrack Treadmill and Weight Limit of Sole Treadmill here.

Conclusion

I have shared my experience regarding the treadmill belt slows down or stop issue when I step on it.

If you are experiencing the same issue, feel free to share it in the comment box below.